MTU is one of the world’s leading manufacturers of large diesel engines and complete propulsion systems. MTU brand engine is produced by the top one heavy duty diesel manufacturer in the world, which has awarded the highest honour. From one hundred years ago until now MTU always is the outstanding delegate of the highest quality in industry, it is widely applied in marine、heavy duty auto、railway vehicles、mines、electric station and so on. As the supplier of marine、railway motor system and land diesel generators’ engine, MTU is world famous with advanced technology、high reliability and top-ranking service. In the military market, MTU always occupy 80% of this market.

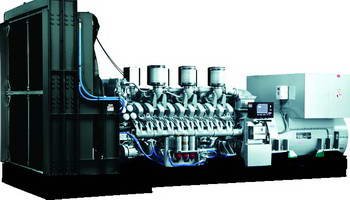

MTU series DG set is assembled with MTU 2000 series and 4000 series diesel engine, and customer-chose alternator. This product completely meets ISO 3046、ISO 4001、ISO 8525、IEC 34-1、GB1105、GB/T2820、CSH 22-2、VDE 0530 and YD/T 502-2000 standards etc.

Futures:

◆ More than three hundreds engine states & fault codes.

◆ Electronic management system(2000 series MDES、4000 series ADEC)—MDEC’s performance is excellent, it can furthest perfect engine’s performance.

◆ Fuel consumption rate is lowest in all of the world.

◆ The longest working life, the first overhauling is more than 24000 hours.

◆ Perfect alarm system, fault auto- diagnosis and auto-display, intellectualized operation.

key technologies:

> Turbocharging: key technology for high-performance engines.

> Common Rail Fuel Injection: Key technology for clean and economical combustion.

> Electronic Engine Management: Key technology for the intelligent control of the drive system

> Exhaust Gas Recirculation: Internal engine technology for reducing nitrogen oxide emissions

> Diesel Particulate Filter: Exhaust aftertreatment for the reduction of soot emissions.

> Selective Catalytic Reduction: Exhaust aftertreatment for reducing nitrogen oxide emissions.

Notes: (1) 50Hz/60Hz. Also avaliable in the following voltage:LV (400)380-690V, MV 3.3KV-13.8KV. (2) The weights are approximate. |

||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||